Materials

Components

We elaborately select the materials and use only refined, certified, and time-proven components. Our success relies on advanced technologies, high-class equipment and experienced specialists.

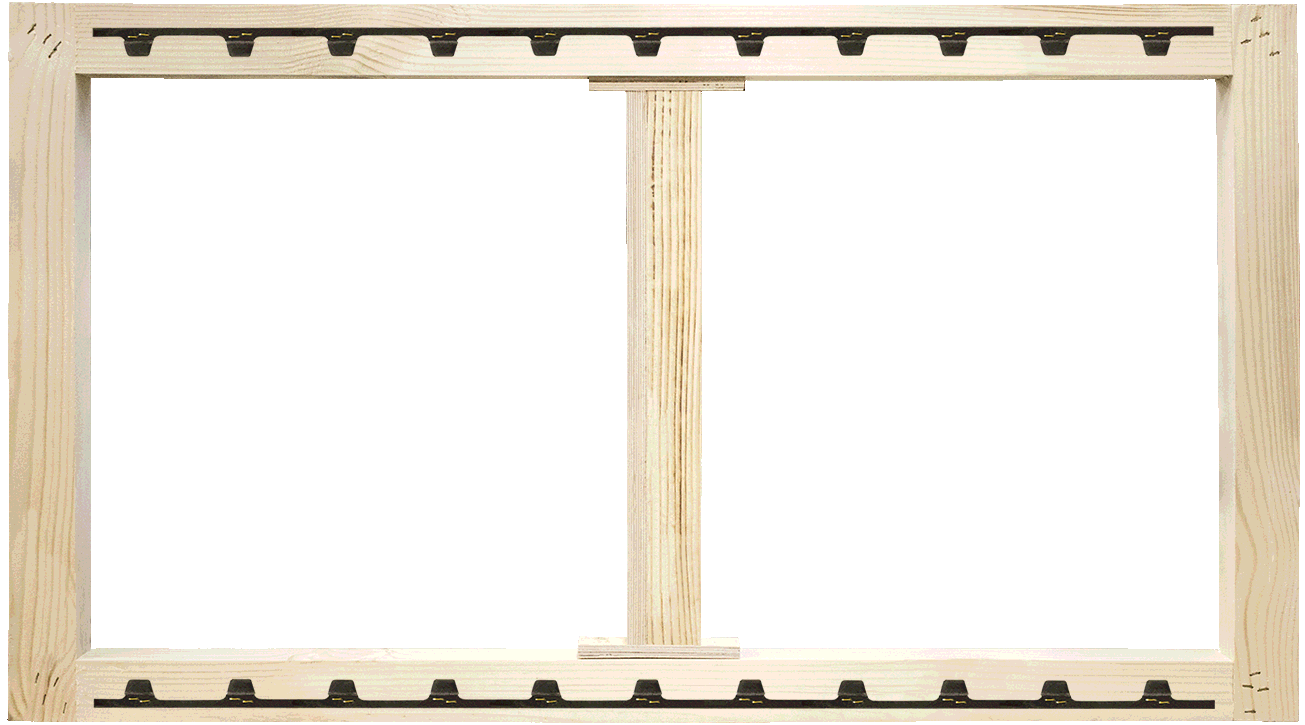

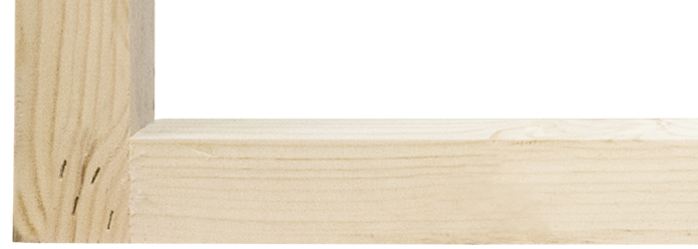

Frame

We produce our frames from solid wood. The spring box is installed horizontally to ensure a dependable basis for the sleeping place. This construction proves to be more durable and guarantees an extension bed effect with even load distribution.

The frame is made from solid wood — a material consisting of genuine timber with no snubs, cavities, pitch pockets and other formations. Our conifer and softwood materials preserve a specific moisture rate (6-12%). Otherwise, the timber is exposed to checking, share fractures and warp. Our specialist fit special beams in the cradle centre to enforce the frame construction.

Solid wood

Locking

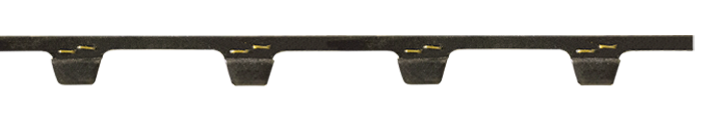

Clip strips

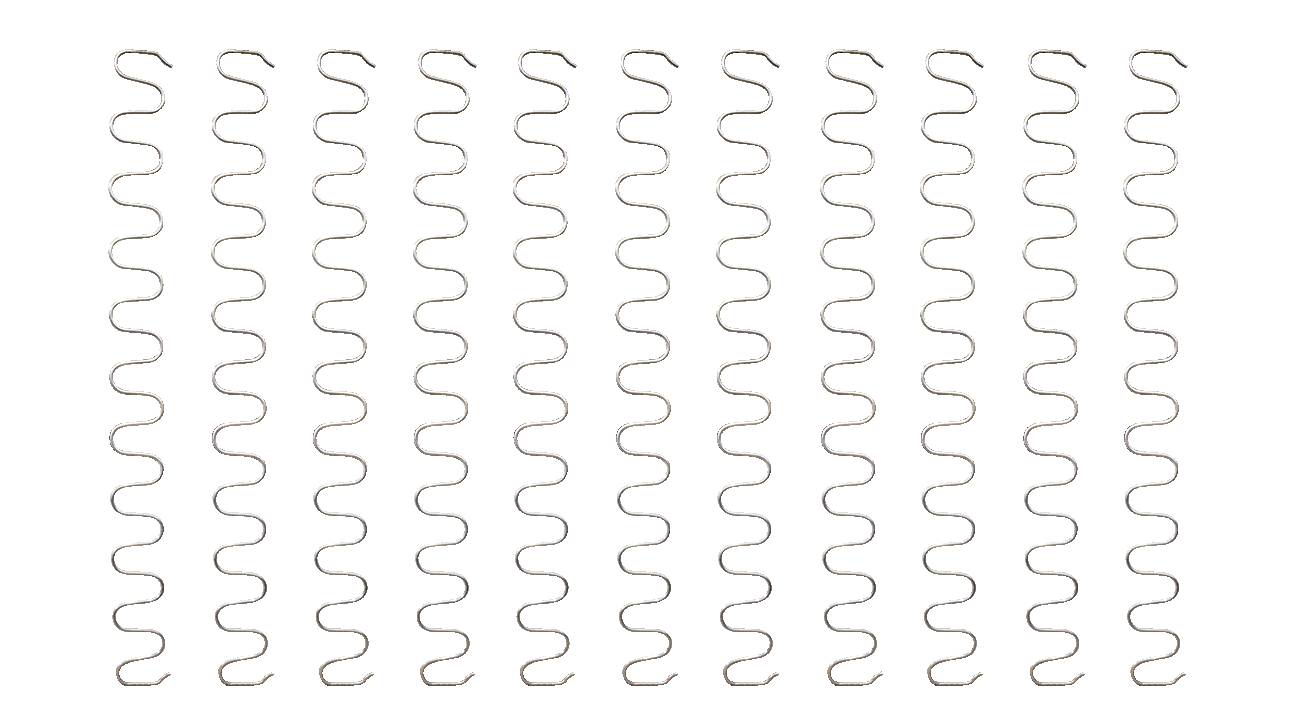

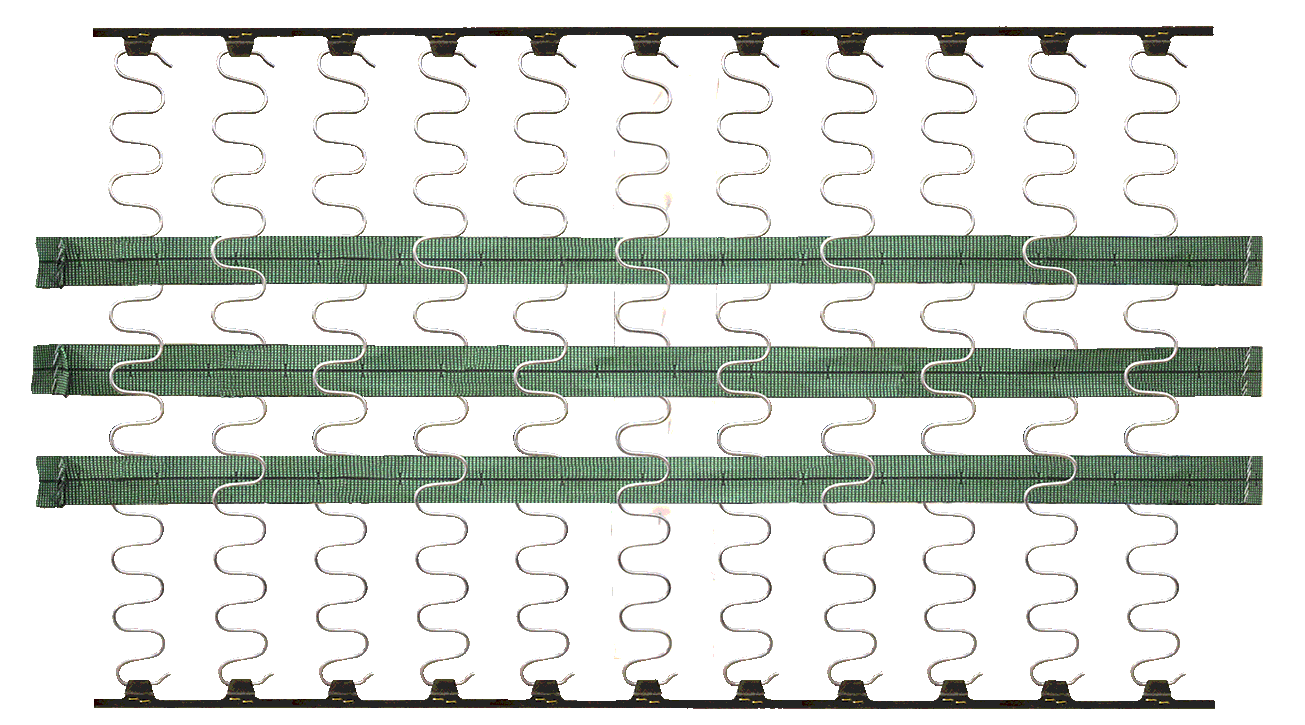

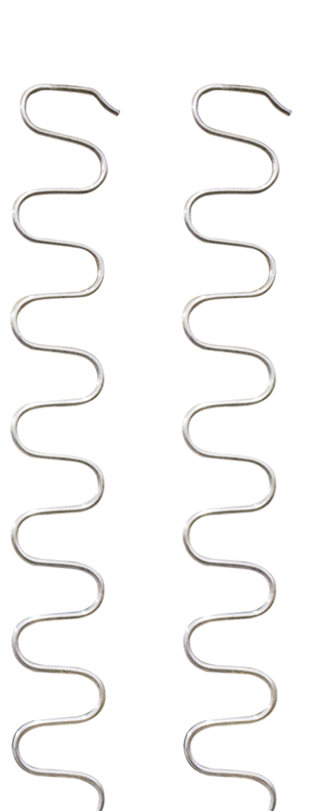

Serpentine spring

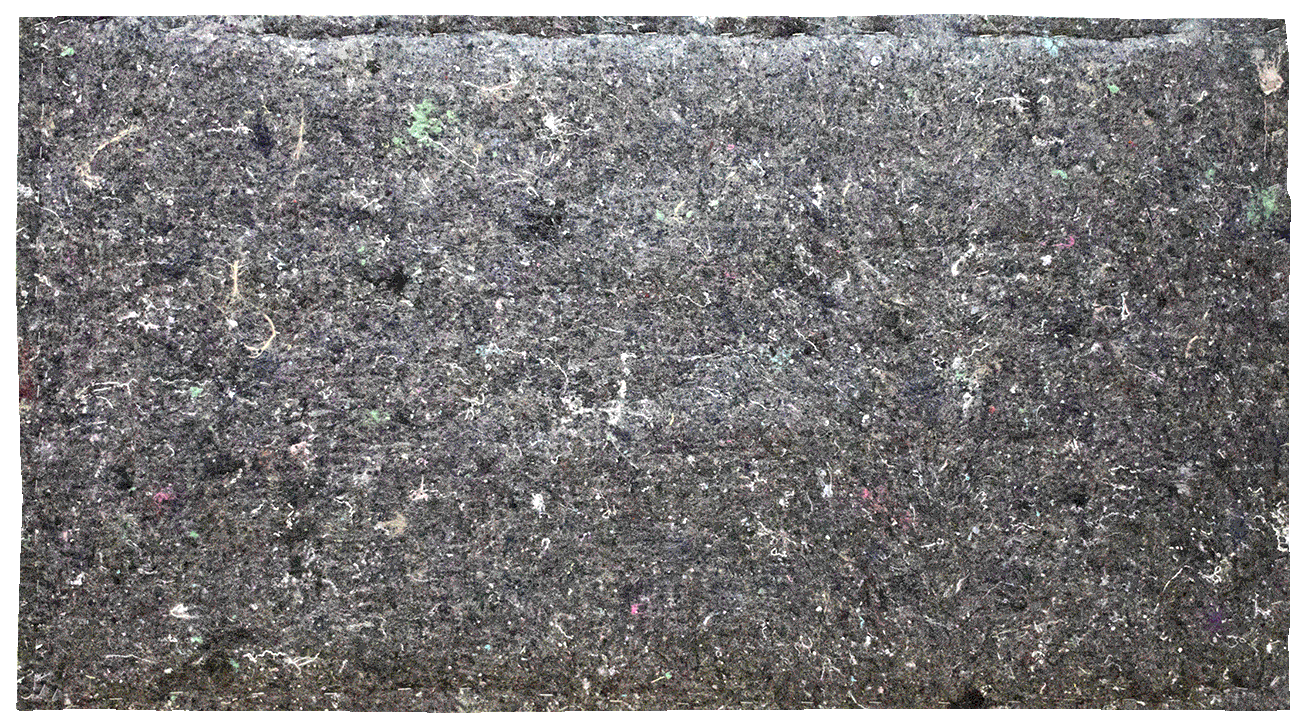

Thermo-felted cloth

Furniture bands

Frame durability is ensured due to particular junctions constructed via interlocking machines. Some manufacturers neglect this technology and execute the elements manually, making them less durable and liable to defects during the service. The entire locking system is sealed by particular humidity-resistant german glue. It provides squeak-free maintenance and also keeps the clinches solidly fixed.

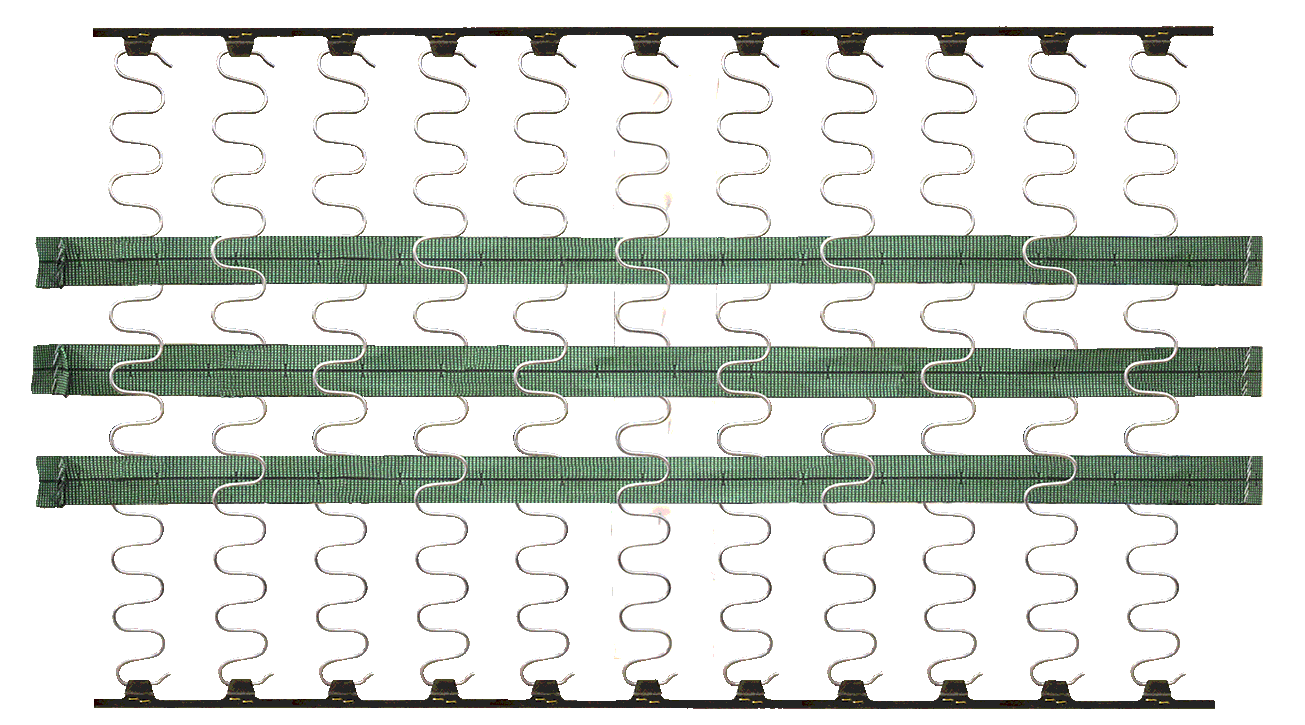

We use OKE clip strips to ensure equal spacing between the serpentine spring elements. This construction proves to be more durable and guarantees an extension bed effect with even load distribution. The clip strips are squeak-free, made of virgin resin and withstand a load of no less than 80 kilos per element.

The zig-zag spring is made of durable galvanised steel exposed to high temperatures. The process ensures a top level of springing, isn't subject to worn-out matters, doesn't sway. Serpentine springs prove to be a brilliant air ventilation system resulting in fast dry out of possible moisture emerging during usage.

European rubber-textile bands support spring elements in a criss-cross manner. This mechanism ensures the efficiency of the entire spring unit. The elements prove to be outstandingly durable and allow daily use of the furniture product.

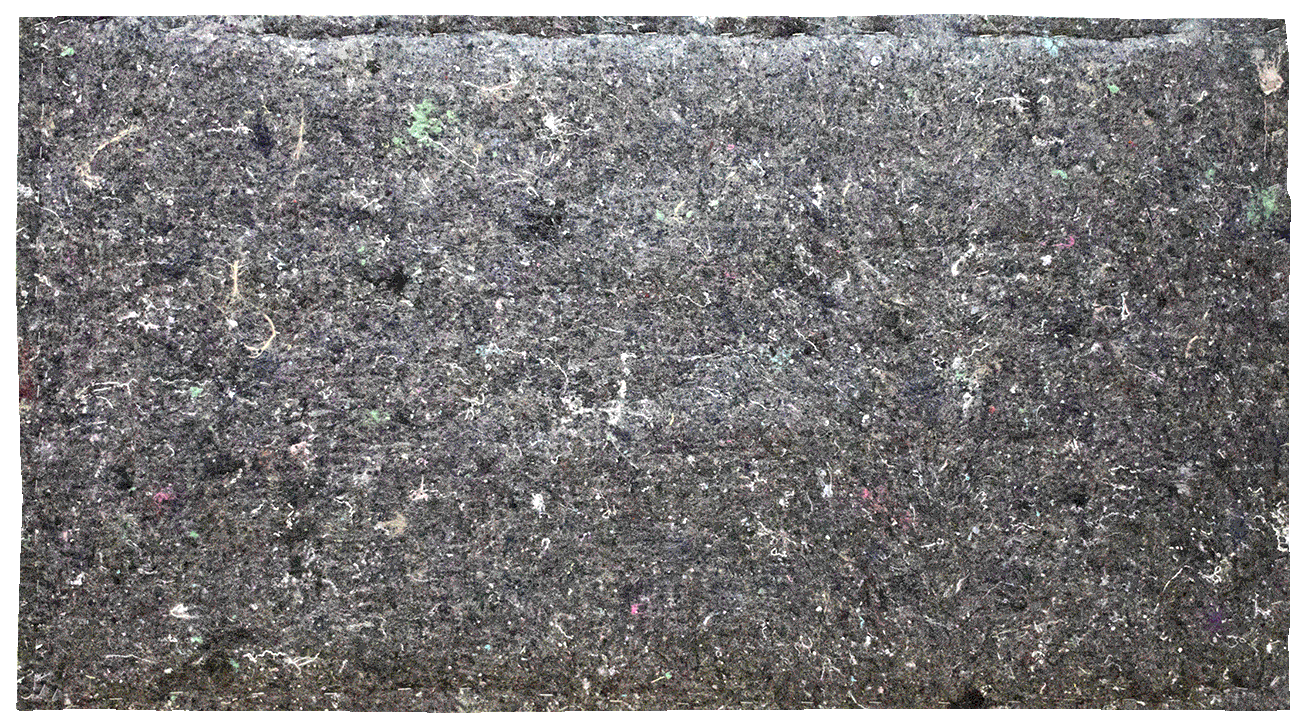

Prior to foam spreading, we cover springs with a thermo-felted cloth to protect the foamed polyurethane and neutralise unpleasant spring feeling. Thermo felt is an eco-friendly material pressed by preheated rollers. This process provides a specific shell and boosts the durability of the entire construction.

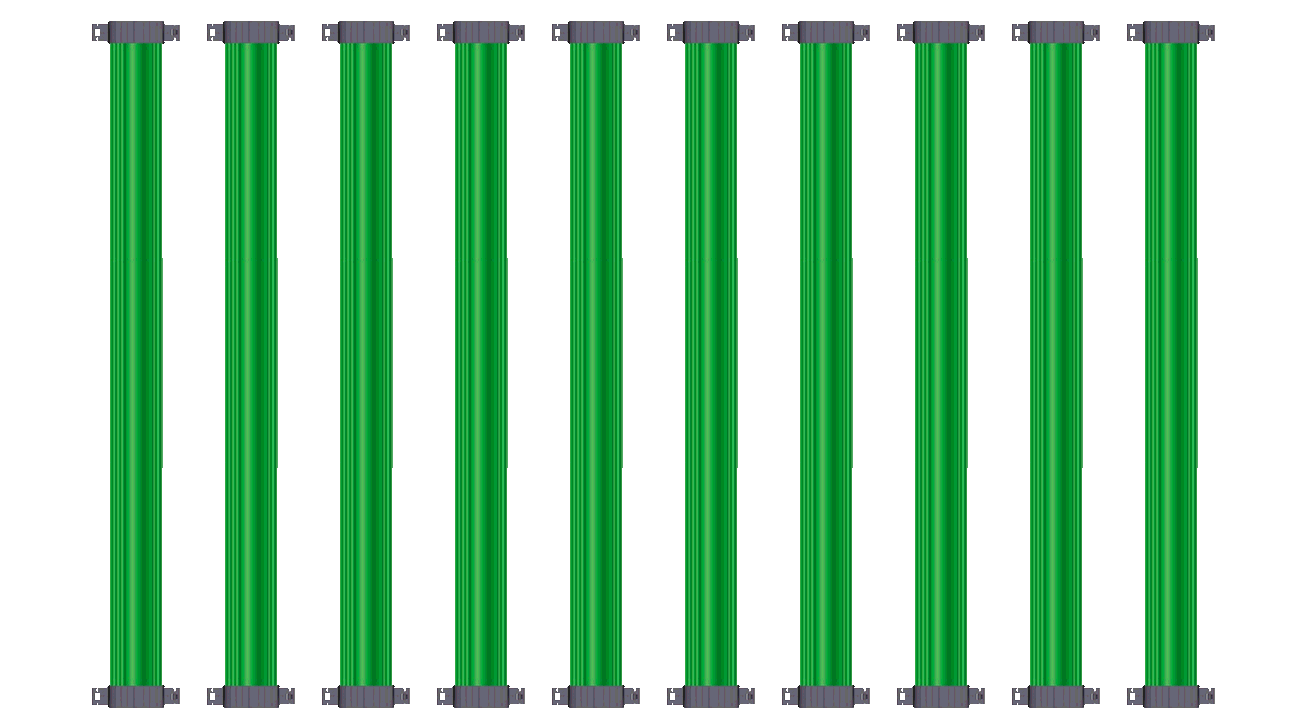

Goodside plastic slats

GOODSIDE plastic slats appear to be an innovation in the furniture market. These plastic slats are constructed of reinforced glass fibre. Goodside elements provide moulding and damped structure to support the back in any body position. The entire technology proves to be orthopaedic.

The frame is made from solid wood — a material consisting of genuine timber with no snubs, cavities, pitch pockets and other formations. Our conifer and softwood materials preserve a specific moisture rate (6-12%). Otherwise, the timber is exposed to checking, share fractures and warp. Our specialist fit special beams in the cradle centre to enforce the frame construction.

Solid wood

Locking

Clip strips

Serpentine spring

Thermo-felted cloth

Furniture bands

Frame durability is ensured due to particular junctions constructed via interlocking machines. Some manufacturers neglect this technology and execute the elements manually, making them less durable and liable to defects during the service. The entire locking system is sealed by particular humidity-resistant german glue. It provides squeak-free maintenance and also keeps the clinches solidly fixed.

We use OKE clip strips to ensure equal spacing between the serpentine spring elements. This construction proves to be more durable and guarantees an extension bed effect with even load distribution. The clip strips are squeak-free, made of virgin resin and withstand a load of no less than 80 kilos per element.

The zig-zag spring is made of durable galvanised steel exposed to high temperatures. The process ensures a top level of springing, isn't subject to worn-out matters, doesn't sway. Serpentine springs prove to be a brilliant air ventilation system resulting in fast dry out of possible moisture emerging during usage.

European rubber-textile bands support spring elements in a criss-cross manner. This mechanism ensures the efficiency of the entire spring unit. The elements prove to be outstandingly durable and allow daily use of the furniture product.

Prior to foam spreading, we cover springs with a thermo-felted cloth to protect the foamed polyurethane and neutralise unpleasant spring feeling. Thermo felt is an eco-friendly material pressed by preheated rollers. This process provides a specific shell and boosts the durability of the entire construction.

Goodside plastic slats

GOODSIDE plastic slats appear to be an innovation in the furniture market. These plastic slats are constructed of reinforced glass fibre. Goodside elements provide moulding and damped structure to support the back in any body position. The entire technology proves to be orthopaedic.

Filler Materials

To reinforce the orthopaedic effect, we use a specific type of foamed polyurethane, the equivalent of the Italian technologies standard. Each filler type has different levels of density, stiffness and viscosity coefficient depending on the purpose.

Glue

We use adhesives of top-notch European and Russian brands with low-combustible and scent-free features.

We use adhesives of top-notch European and Russian brands with low-combustible and scent-free features.

ST 3040

Our fabric uses solid sheets of polyurethane foam ST3040 prominent for resilience, low remaining strain, outstanding levels of durability, superior elasticity and restorability. The density-stiffness ratio equals 30 kg/m3 of PU foam to 40 MPa and appears to be a perfect combination for daily-use sofa beds.

Our fabric uses solid sheets of polyurethane foam ST3040 prominent for resilience, low remaining strain, outstanding levels of durability, superior elasticity and restorability. The density-stiffness ratio equals 30 kg/m3 of PU foam to 40 MPa and appears to be a perfect combination for daily-use sofa beds.

HR

This extra-soft foam filler is famous for its heterogeneous cell patterns. The elements have a particular response to the load depending on the size of each cell. This feature contributes to elasticity and comfort.

This extra-soft foam filler is famous for its heterogeneous cell patterns. The elements have a particular response to the load depending on the size of each cell. This feature contributes to elasticity and comfort.

Memory foam

Memory foam is a ground-breaking viscoelastic polyurethane material with a memory effect. The foam instantly moulds to the shape of your body due to specific structure maintained by numerous capsules ensuring pressure-free support.

Memory foam is a ground-breaking viscoelastic polyurethane material with a memory effect. The foam instantly moulds to the shape of your body due to specific structure maintained by numerous capsules ensuring pressure-free support.

ELAX

ELAX contains an innovative polymeric matrix exclusively developed by R&D labs with consideration to healthy sleep studies. The material features specific cells of various sizes, which provide an even load dispatch and relax the muscles and the spine.

ELAX contains an innovative polymeric matrix exclusively developed by R&D labs with consideration to healthy sleep studies. The material features specific cells of various sizes, which provide an even load dispatch and relax the muscles and the spine.

Choose the element to learn more

Crisps

Polyurethane strips of moderate size and stiffness (including memory foam) are blended with holofiber. This feature ensures the pillows remain wearproof and resilient.

Polyurethane strips of moderate size and stiffness (including memory foam) are blended with holofiber. This feature ensures the pillows remain wearproof and resilient.

Hollcon

This airy and bouncy material actively resists compression due to spiral silicon-covered polyester fibre. The construction is moisture-resistant and possesses brilliant material recoverability proving hollcon to be an excellent quilted product.

This airy and bouncy material actively resists compression due to spiral silicon-covered polyester fibre. The construction is moisture-resistant and possesses brilliant material recoverability proving hollcon to be an excellent quilted product.

Filler Materials

To reinforce the orthopaedic effect, we use a specific type of foamed polyurethane, the equivalent of the Italian technologies standard. Each filler type has different levels of density, stiffness and viscosity coefficient depending on the purpose.

Glue

We use adhesives of top-notch European and Russian brands with low-combustible and scent-free features.

We use adhesives of top-notch European and Russian brands with low-combustible and scent-free features.

ST 3040

Our fabric uses solid sheets of polyurethane foam ST3040 prominent for resilience, low remaining strain, outstanding levels of durability, superior elasticity and restorability. The density-stiffness ratio equals 30 kg/m3 of PU foam to 40 MPa and appears to be a perfect combination for daily-use sofa beds.

Our fabric uses solid sheets of polyurethane foam ST3040 prominent for resilience, low remaining strain, outstanding levels of durability, superior elasticity and restorability. The density-stiffness ratio equals 30 kg/m3 of PU foam to 40 MPa and appears to be a perfect combination for daily-use sofa beds.

HR

This extra-soft foam filler is famous for its heterogeneous cell patterns. The elements have a particular response to the load depending on the size of each cell. This feature contributes to elasticity and comfort.

This extra-soft foam filler is famous for its heterogeneous cell patterns. The elements have a particular response to the load depending on the size of each cell. This feature contributes to elasticity and comfort.

Memory foam

Memory foam is a ground-breaking viscoelastic polyurethane material with a memory effect. The foam instantly moulds to the shape of your body due to specific structure maintained by numerous capsules ensuring pressure-free support.

Memory foam is a ground-breaking viscoelastic polyurethane material with a memory effect. The foam instantly moulds to the shape of your body due to specific structure maintained by numerous capsules ensuring pressure-free support.

ELAX

ELAX contains an innovative polymeric matrix exclusively developed by R&D labs with consideration to healthy sleep studies. The material features specific cells of various sizes, which provide an even load dispatch and relax the muscles and the spine.

ELAX contains an innovative polymeric matrix exclusively developed by R&D labs with consideration to healthy sleep studies. The material features specific cells of various sizes, which provide an even load dispatch and relax the muscles and the spine.

Наведите на любой из элементов

Crisps

Polyurethane strips of moderate size and stiffness (including memory foam) are blended with holofiber. This feature ensures the pillows remain wearproof and resilient.

Polyurethane strips of moderate size and stiffness (including memory foam) are blended with holofiber. This feature ensures the pillows remain wearproof and resilient.

Hollcon

This airy and bouncy material actively resists compression due to spiral silicon-covered polyester fibre. The construction is moisture-resistant and possesses brilliant material recoverability proving hollcon to be an excellent quilted product.

This airy and bouncy material actively resists compression due to spiral silicon-covered polyester fibre. The construction is moisture-resistant and possesses brilliant material recoverability proving hollcon to be an excellent quilted product.

Certificates of Compliance

Textiles

Distinctiveness and quality are of top priority for our brand. We thoroughly select favourable

textiles and order only those samples that comply with the requirements of our brand. We

offer more than 250 textile collections and 3750 colours to delight the customers guaranteed

by our elaborate approach. You are sure to find your dream design!

textiles and order only those samples that comply with the requirements of our brand. We

offer more than 250 textile collections and 3750 colours to delight the customers guaranteed

by our elaborate approach. You are sure to find your dream design!

Hopsack is a durable textile with a specific chequy pattern. The weave adds a natural character to the texture. Colour-blend weave ensures a smooth finish.

Velvet is a nonwoven velour-like material with brilliant usability characteristics and deformation-proof features. The textile is durable and nice to the touch.

The exact fabric imitation of real material. The textile saves visual resemblance but appears to be much more durable.

Hi-tech transpiring material ensures to be freeze-proof and abrasion-resistant. The manufacturer guarantees to avoid polyvinyl chloride components.

This textile is celebrated for its soft velvety pile surface. The manufacturers use five threads to create the texture; four threads are paired to weave the basis, while the fifth thread is needed to form the pile.

To produce the textile, manufacturers use extra thin fibres. This process guarantees softness, velvety feeling and excellent durability.

Durable textile with a high-density level and velvety structure. It contains warp threads and woven fleecy nap. The material is wearproof and affordable.

This universal unwoven textile possesses a particular pile structure on the face. Flocked upholstery is often regarded as animal-friendly, wearproof and children-friendly. It is hardly possible to damage the surface.

These fabrics introduce complex woven patterns. Manufacturers use 24 threads to create the weaving unit, making the textile perfect for upholstery needs and resistant to daily wear and tear.

Storage Unit

Storage unit frames are made from laminated chipboard. All materials are CARB and FSC

certified. Laminated chipboard is resistant to moisture and mould, doesn't crack or peel. We

use a fibreboard featuring an air vent to relieve the construction load. 1 mm ABS plastic

strips are fitted on the sawn edge to protect humidity and evaporation. The material proves

to be outstandingly durable, is resistant to physical impact and thermal influence. The

maximum load, the bottom of the container, can endure is 15 kg.

certified. Laminated chipboard is resistant to moisture and mould, doesn't crack or peel. We

use a fibreboard featuring an air vent to relieve the construction load. 1 mm ABS plastic

strips are fitted on the sawn edge to protect humidity and evaporation. The material proves

to be outstandingly durable, is resistant to physical impact and thermal influence. The

maximum load, the bottom of the container, can endure is 15 kg.

Certificates of Compliance

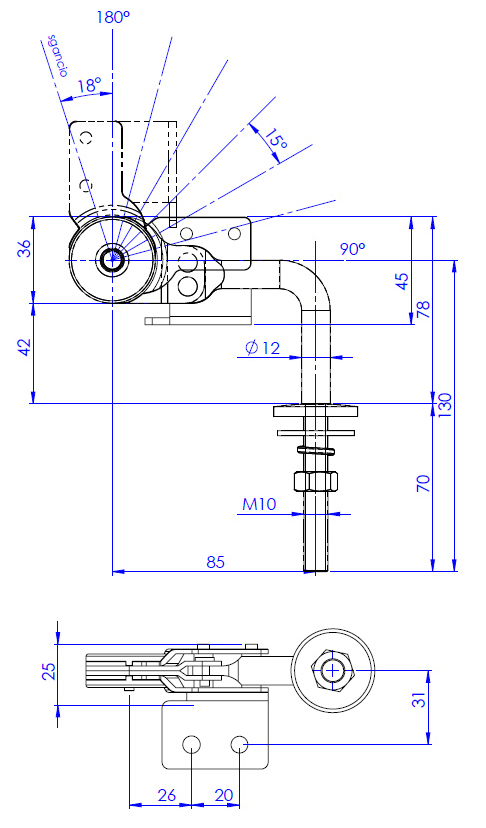

Mechanisms

Our models feature Italian (LOIUDICE), Polish (STALMOT) and Russian (KomKor, T.REST)

developments. Enforced transformation mechanisms are powder coated and corrosion - resistant. We have exclusively modified the elements to increase durability during everyday use. Most components have no welded seams and are made using advanced laser cutting technologies. The installation is hidden inside the frame, possesses smooth

running, features stepless shift adjustment and prevents linen jam.

developments. Enforced transformation mechanisms are powder coated and corrosion - resistant. We have exclusively modified the elements to increase durability during everyday use. Most components have no welded seams and are made using advanced laser cutting technologies. The installation is hidden inside the frame, possesses smooth

running, features stepless shift adjustment and prevents linen jam.

Certificates of Compliance, Patents