To estimate upholstery durability, manufacturers and independent quality control professionals run a range of service tests, including abrasion, pilling, tenacity resistance, binding, finish, servicing, cleaning and use.

Abrasion hardness complements the wear-resisting properties and appears to be the most valuable criterion to estimate the quality of the upholstery and textile, shaping the end-user performance. The estimated index outlines the material’s suitability to accommodate various purposes. The higher the abrasion hardness is, the more usable the fabric is.

The market introduces several tests to estimate the textile abrasion hardness:

- Martindale abrasion test famous in Europe

- Wyzenbeck test is prevailing in the USA and countries of South America.

- Stoll test is used to estimate the usability of nap fabric via exposing the material against the rubber surface.

The tests feature different mechanisms. Therefore, sailing through one trial cannot guarantee that the other two standards will qualify the material as top-notch.

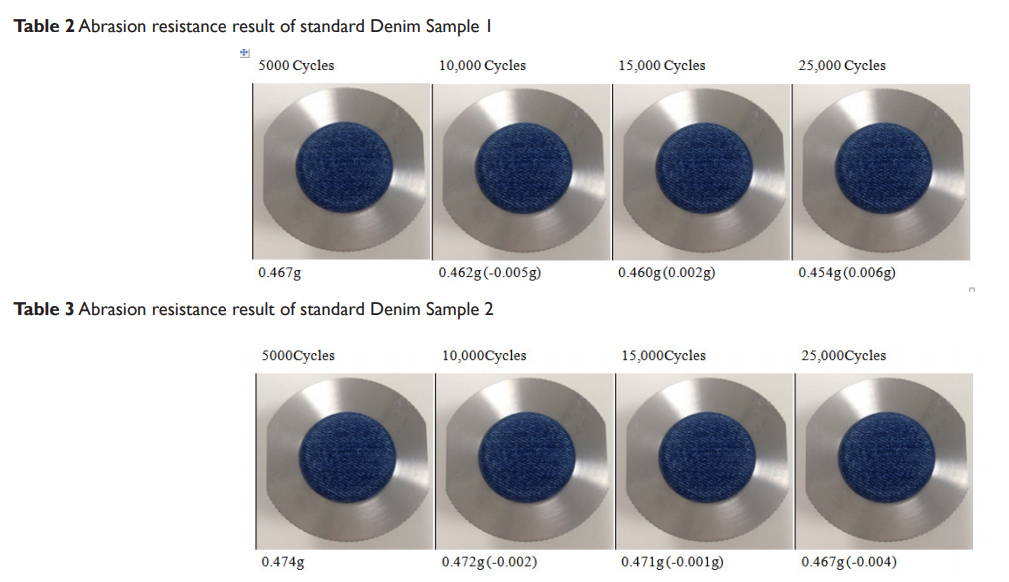

Martindale Abrasion Test

The process ensures a vibrational coupling in which the upholstery sample is rubbed against the standard abrasive wool surface with a particular force. The movement repeats a figure-eight pattern. The non-stop trial depends on the material’s durability characteristics and can take up to several days. Once the inherent actions are completed, the specialists estimate the number of rubs endured by the textile sample before it gains an unfavourable look (breakage, severe wrinkles, holes). The rub index is outlined by the degree of abrasion.

Martindale Abrasion Test Classification

The British Standards Institution defines a classification scale that divides textile materials into three categories:

- Heavy Use

- Normal Use

- Light Use